Forged pipe and fittings provide high-strength, leak-proof solutions for high-pressure systems. Products include forged pipes, hollow tube forgings, and fittings such as elbows, tees, reducers and flanges. Manufactured to ASME B16.11 and other international standards, they ensure durability, pressure resistance, and reliable sealing for oil, gas, chemical, marine and power industries.

Quick Specs at a Glance

- Types Available: Forged Pipe (large-diameter, thick-wall, hollow section), Forged Fittings (Socket Weld / Threaded, elbows, tees, reducers, flanges)

- Standards: ASME B16.11, ASTM, EN, GB

- Alloy Options: Aluminum alloys 6061, 7075, 5083, 2024, 7050, 2219; titanium and various steel grades (alloy steel, high-alloy steel) available on request.

- Size Range: OD 191–813 mm (7 ½"–32") · Wall Thickness 25–165 mm (1"–6 ½") · Length up to 13.8 m (45 ft)

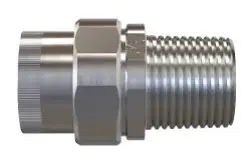

Forged Pipe Fittings – Socket Weld & Threaded to ASME B16.11

Forged fittings are essential for high-pressure piping systems, combining leak-proof strength with precise tolerances. Manufactured to ASME B16.11, they are available in threaded, socket weld, and butt-weld types across multiple pressure classes, ensuring reliability in demanding oil & gas, chemical, marine, and power generation environments.

- Standards: ASME B16.11 certified, Class 150 / 300 / 600 / 2000 / 3000 / 6000

- Connection Types: Threaded, Socket weld, Unthreaded (butt-weld)

- Shapes: Elbow, tee, reducer, flange, coupling, union, plug, cap, cross

Threaded Fittings (NPT/BSP, Class 150/300/600, 1/2"–4")

Forged threaded elbow for small-bore pipelines; 45°/90°; Class 150/300/600; sizes 1/2"–4".

Threaded Tee (NPT/BSP)

Equal / reducing tee; leak-tight threads; Class 150/300/600; common in air piping & chemical lines.

Threaded Coupling

Full / half coupling; NPT/BSP; sizes 1/2"–4"; quick installation without welding.

Threaded Union

Easy assembly/disassembly for maintenance; leak-proof sealing; Class 150/300/600.

Forged Pipe Nipple

Close / hex / reducing nipple; NPT/BSP; sizes 1/2"–4"; for transitions and extensions.

Hex Bushing (Threaded)

Thread reducer/adaptor; NPT/BSP; compact design; corrosion-resistant finishes available.

Socket Weld Fittings (ASME B16.11)

45°/90° forged elbow; Class 3000/6000; ideal for high-pressure piping in oil & gas, marine and chemical.

Socket Weld Tee

Equal / reducing tee; forged to ASME B16.11; pressure Class 3000/6000; used in distribution headers.

Socket Weld Reducer

Concentric / eccentric; smooth flow transition; pressure Class 3000/6000; precision-forged ends.

Socket Weld Cross

Equal / reducing cross; forged to ASME B16.11; provides four-way branch for compact piping layouts.

Socket Weld Cap

End closures for pipelines; forged to withstand Class 3000/6000 pressure; corrosion-resistant alloys.

Branch Outlets (Sockolet / Threadolet)

Run-pipe connections for headers; forged branch outlets to ASME B16.11; high-pressure reliability.

Unthreaded / Butt-Weld Fittings

Permanent welded joint for larger bore lines; smooth radius for reduced turbulence.

Butt-Weld Reducer

Concentric / eccentric for stable flow; suits chemical, nuclear and heavy industry.

Stub End (Lap Joint)

Used with lap-joint flanges for frequent assembly; corrosion-resistant options.

In addition to the standard socket weld, threaded and butt weld types, Chalco also supplies special forged fittings such as street elbows, half couplings and customized reducers. Contact us today for detailed specifications and a fast quote.

Forged Pipe & Tube Solutions – Large Diameter & Thick-Wall

Forged pipes serve high-pressure and critical service with dense grain structure, uniform wall thickness, and superior fatigue strength—ideal for long-life, leak-proof systems. Typical configurations include large-diameter and thick-wall forged hollows, with pressure classes from 2000 to 6000 lb for demanding service.

Available in forged hollows or bored-from-solid routes, these pipes enable tight ID/OD and concentricity control with optional UT/RT and heat treatment (T6/T651/T7451).

- Features: Large-diameter, thick-wall, seamless forged construction; extended fatigue life

- Manufacturing Routes: Near-net forged hollows; bored-from-solid with deep-hole drilling

- Quality Options: Heat treatment (T6/T651/T7451), NDT (UT/RT), EN 10204 3.1 on request

-

Forged Aluminum Pipe Hollow

Near-net hollow forging for large-diameter and thick-wall shells; dense structure and reliable pressure performance.

-

Bored-from-Solid Aluminum Pipe Hollow

Solid billet route with deep-hole drilling/boring to target ID and wall—preferred when geometry or stock favors solid processing.

-

Thick-Wall Forged Aluminum Pipe Hollow

High wall-thickness with tight concentricity control for pressure service; heat-treated and UT/RT per drawing.

-

Heat-Treated Forged Aluminum Pipe Hollow

Supplied with T6/T651/T7451 for strength and stability; optional UT/RT and EN 10204 3.1 certification.

Note: Forged tubes are also available for aerospace/precision structures when lightweight stiffness, tight ID/OD tolerance, or non-round geometry is required.

-

Forged Aluminum Tube – Precision Aerospace Grade

Round tube hollows for thin to mid wall precision requirements with tight ID/OD tolerances, straightness, and concentricity control; suitable for aerospace hydraulics, precision frames, and weight-sensitive assemblies. Heat treatment and NDT available on request.

-

Forged Aluminum Tube Hollow – Custom Shapes (Square, Oval, Flanged Ends)

Square or oval hollows and flanged-end designs for space-limited or interface-rich assemblies with consistent alloy and temper to match adjoining parts.

Manufacturing & Quality Assurance

Chalco offers comprehensive forging capabilities including open-die forging for large hollows and long tubes, closed-die forging for precision and complex fittings, and rolled ring forging for circular parts such as flanges and vessel shells. Combined with advanced heat treatment and CNC machining, these processes ensure stable grain flow, tight dimensional tolerance, and the flexibility to meet both heavy-duty and precision-demanding projects.

Every forged product is supported by a strict quality assurance system. Dimensional accuracy, heat treatment stability, and mechanical properties are verified throughout production, with optional UT/RT inspection and EN 10204 3.1 traceable certification available. This guarantees long-term reliability and compliance for critical applications in aerospace, oil & gas, nuclear, marine, and defense sectors.

- Processing Range: OD 20–800 mm; Wall ≥5 mm; Length up to 1500 mm

- Machining Capability: Deep-hole drilling/boring; CNC finish turning tolerance up to ±0.05 mm

- Heat Treatment: T6, T651, T74, T76 available by alloy/spec

- Quality Standards: ASTM, ASME, EN, GB, MIL standards

- NDT Options: UT/RT, hardness, tensile, and mechanical testing

- Documentation: EN 10204 3.1 material certs, heat-treatment reports

- Traceability: Heat-number tracking and process record retention

- Packing: Export packaging with ID/OD protection for safe global delivery

Industry Applications – Forged Pipe, Tube & Fittings

Chalco supplies forged aluminum pipes, tubes, and fittings for critical industries where lightweight strength, fatigue resistance, and corrosion performance are required. Applications span aerospace, oil & gas, chemical, petrochemical, nuclear, marine, defense, power generation, air piping and pressure vessels, with alloys and processes tailored to each environment.

Oil & Gas – High-Pressure Pipelines & Offshore Systems

Alloy Recommendation: 6061, 5083, 7075

Features: High-pressure resistance, corrosion protection, UT/RT & 3.1 certs

Chemical, Petrochemical & Nuclear – Corrosion-Resistant Thick-Wall Hollows

Alloy Recommendation: 5083, 6061, 2219

Features: Corrosion resistance, traceable batches, heat-treated documentation

Aerospace – Actuators, Housings & Structural Tube Shells

Alloy Recommendation: 7075, 7050, 6061

Features: High strength, concentricity control, anodizing-ready surfaces

Defense & Military – Load-Bearing Tube Shells

Alloy Recommendation: 7075, 7050

Features: Impact resistance, vibration tolerance, precision alignment

Marine & Rail – Cooling Modules & Corrosion-Resistant Shells

Alloy Recommendation: 5083, 6061

Features: Seawater resistance, fatigue life, protective finishes

Power Generation – Turbines, Boilers & Steam Lines

Alloy Recommendation: 6061, 2219

Features: Heat resistance, pressure fatigue strength, precision-bored hollows for turbine/boiler systems

Machinery & Industrial – Hydraulics, Compressors & Manifolds

Alloy Recommendation: 6061, 7075

Features: Wear resistance, vibration tolerance, tight ID/OD control for hydraulic cylinders

Air Piping – Compressed Air & Industrial Pipework

Alloy Recommendation: 6061, 2219

Features: Leak-free socket weld & threaded fittings; durable for compressed air systems

Fast Quote: To receive a tailored quotation, please include: Alloy & Temper · OD/ID/Wall · Length · Quantity · Drawing/Tolerances · NDT (UT/RT) requirements.

Knowledge Center & FAQs — Forged Aluminum Pipe, Tube & Fittings

Open-Die vs Closed-Die vs Rolled Ring Forging

Open-die forging is flexible for large and simple shapes, closed-die forging ensures precision for complex geometries, while rolled ring forging delivers optimized grain flow for hollow rings and pressure components.

Forged vs Wrought Fittings

Wrought fittings are shaped by rolling or extrusion, but forged fittings are compressed under high pressure, achieving denser grain structure and superior pressure resistance.

Aluminum vs Steel vs Titanium

Aluminum forged fittings provide lightweight and corrosion resistance, steel offers maximum load capacity, and titanium achieves extreme strength-to-weight ratios at higher cost.

Forged Pipe vs Extruded/Seamless Pipe

Forged aluminum pipe/tube is produced by forging (near-net hollow or bored-from-solid), giving denser grain flow and better fatigue/pressure resistance. Extruded or drawn products are suited for standard OD/wall but less optimal for large-diameter or ultra-thick applications.

Can aluminum forged fittings comply with ASME B16.11?

Yes. ASME B16.11 specifies dimensions and pressure classes for socket-weld and threaded forged fittings. Chalco supplies forged aluminum fittings manufactured in compliance with these requirements.

What pressure classes are available for forged fittings?

Class 2000 / 3000 / 6000 are available for socket-weld and threaded forged fittings per ASME B16.11.

What sizes can Chalco manufacture for forged pipes and tubes?

Capability covers OD 20–800 mm, wall ≥5 mm, and length up to 1500 mm. Deep-hole boring and CNC machining ensure tight concentricity and tolerance.

Which alloys are available?

Aluminum grades include 6061, 7075, 5083, 2024, 7050, 2219. Custom alloys available on request.

What quality documentation and inspections can be provided?

EN 10204 3.1 certificates, dimensional and heat-treatment reports, plus optional NDT (UT/RT). Mechanical testing can be arranged per specification.

What is the difference between "pipe” and "tube”?

"Pipe” usually refers to pressure-service, large-diameter and thick-wall sections; "tube” emphasizes precision geometry and lighter structures in aerospace and machinery. See more in The difference between pipe and tube.

Can you supply heat-treated and finish-machined parts?

Yes. Heat treatments such as T6/T651/T7451 are available by alloy/spec. CNC finish machining (including deep-hole drilling/boring) is supported to drawing tolerances.

How should I send an RFQ to speed up quotation?

Include Alloy/Temper, OD/ID/Wall, Length, Quantity, Drawing/Tolerances, and required NDT (UT/RT). Our sales team will respond within 24 hours.

Contact & Quick Quote

Chalco supplies forged aluminum pipe, tube, and fittings for critical industries worldwide. With large-diameter and thick-wall capabilities, aerospace-grade precision tubes, and ASME B16.11 forged fittings, we deliver reliable quality with full documentation and fast turnaround.

Ready to get started? Send us your requirements including Alloy/Temper, OD/ID/Wall, Length, Quantity, Drawing/Tolerances, and NDT needs. Our team will provide a precise quotation.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote